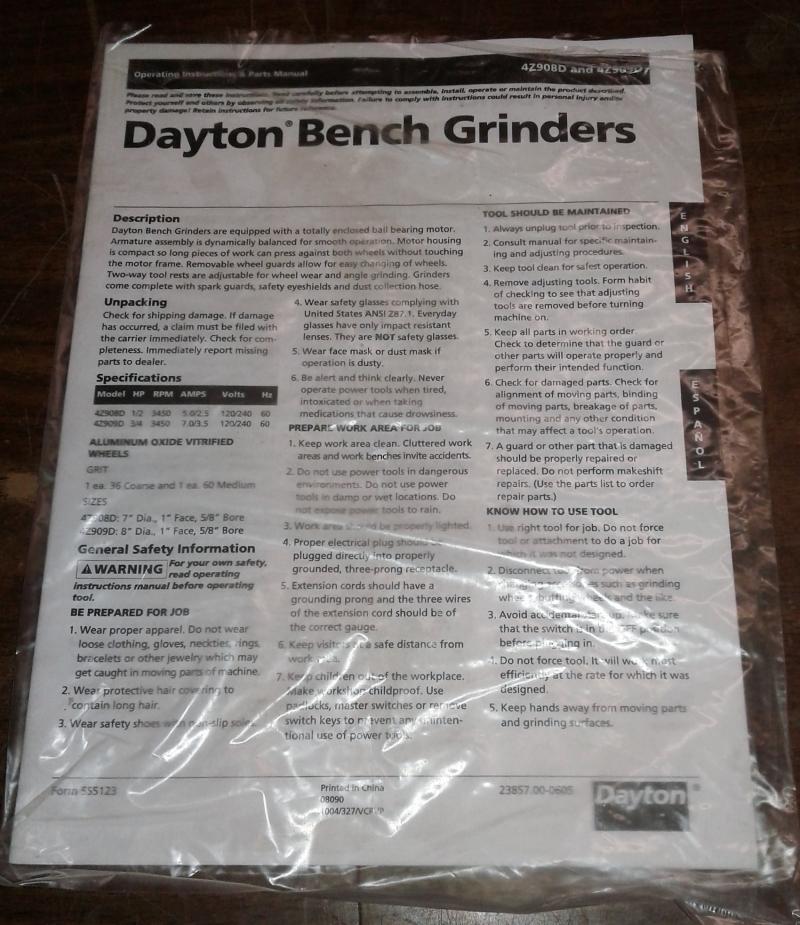

Dayton 8 Bench Grinder Manual

The Vintage Machinery Photo Index is a place where members of this site can submit photos of old woodworking machinery. The Index is a valuable resource in that visitors to this site can see examples of machinery made by many different manufacturers. Submitting Photos If you would like to submit a photo of a machine made by this manufacturer, please.

There are currently 30 Photo Index submissions for this manufacturer. PLEASE NOTE: VintageMachinery.org was founded as a public service to amateur and professional woodworkers who enjoy using and/or restoring vintage machinery.

Find Haynes 1995 Yamaha Virago 1100 XV1100 Repair Manuals at J&P Cycles, your source for aftermarket motorcycle parts and accessories.

Find Haynes 1995 Yamaha Virago 1100 XV1100 Repair Manuals at J&P Cycles, your source for aftermarket motorcycle parts and accessories.

Our purpose is to provide information about vintage machinery that is generally difficult to locate. VintageMachinery.org does not provide support or parts for any machines on this site nor do we represent any manufacturer listed on this site in any way. Catalogs, manuals and any other literature that is available on this site is made available for a historical record only.

Please remember that safety standards have changed over the years and information in old manuals as well as the old machines themselves may not meet modern standards. It is up to the individual user to use good judgment and to safely operate old machinery. The VintageMachinery.org web site will assume no responsibilities for damages or injuries resulting from information obtained from this site. Copyright © 2001 - 2018 VintageMachinery.org (formerly owwm.com) - All rights reserved.

Dayton Bench Grinder Switch

Dayton Bench Grinders Parts

Grinding Wheel Removal With the power off, unscrew the shield, if applicable, that surrounds the grinding wheel. Locate the center arbor nut, and unscrew the nut with a wrench, holding the wheel in one hand so it doesn't rotate. Since the grinding wheel rotates toward you, the right-side wheel nut is threaded as you'd typically expect and unscrews by turning the nut toward the front of the grinder. The left-side grinding wheel nut, in most cases, is reversed and unscrews by turning it toward the back of the grinder in an opposite rotation.

Once unscrewed, remove the nut and the holding washer.